The industrial areas are most often susceptible to various types of damage and corrosion. Those who find themselves taking care of these areas or having to revitalize them are faced with an enormous task. Due to the way their surroundings work, it’s likely that the grating systems and flooring in industrial areas will need some pretty formidable protection. That’s why we are looking into the advantages of GRP grating systems and what these pieces of flooring can offer.

1. Impact resistance

One of the most common types of damage and harm that may impact the floors in an industrial area will always be impact damage. Whether it’s things being carried across the floors or containers bumping into it, it’s likely that the industrial flooring will endure quite a few hits. The less expected hits that may come as a malfunction of the active process within the area could also damage the flooring.

Thankfully, GRP grating systems provide a much better experience with such damages. It will allow the flooring to heavily resist impact damage no matter where it’s coming from. The heavy objects will bounce off of it due to the integrity this system has. You should also find a reliable manufacturer and distributor too considering how important that is to the overall quality.

With the GRP grating systems in play, we suggest you check out https://www.grpgratingsystems.co.uk

2. Corrosion resistance

The second most frequent source of damage will definitely come from corrosion. Corrosion is pretty problematic as is, frequently causing major problems across the board. With flooring, corrosion can lead to failure of structural integrity and potential injuries. On top of injuries, we have the problem of the entire system being compromised and potentially failing.

In this area, we can see that the health of the system stems from its integrity. As with resistance to impact damage, GRP grating systems have some boons to offer. These systems simply aren’t corrosive, being able to endure horribly hostile environments with no problem. They won’t rust and the overall influence that use has on it is very minor. Due to this, they require little maintenance to stay in top shape.

3. Slip resistance

It’s assumed that across the life of the grating system, it’ll endure a ton of walking across it and support a lot of traffic. This traffic should be as safe as possible and maintain consistency. The most troublesome problem in this department is how slippery the floor is.

The floor’s slipperiness can affect many things. Any form of transporting containers can run into the problem of being dangerous to transport. Slowing down the entire process for the sake of safer execution. Of course, it’d be better if we could reduce the worry of slippery floors as much as possible. This is done through GRP grating systems’ ability to reduce slips on these floorings. It has been estimated that the reduction of slips goes up to over 30% even. In a way, reducing injuries also positively affect financial situations. If we don’t have to shell out cash for the sake of paying for our employee’s recovery we are much better off. With the less slippery foes, it’s much easier to maintain that safety.

4. Resistant to elements

Along with all the other resistances we also get resistance to elements. The first one of these is resistance to fire. The fire resistance will come in handy for those areas that are frequently under high temperatures and may have an insane amount of troublesome heat to deal with. Don’t be worried about electricity either. Considering the GRP grating systems are non-conductive, the electricity will not be a danger to our workers or machines.

If you want to employ a proper and safe source of flooring, it’s worthwhile to install the GRP grating systems. Even if you get an unexpected source of damage that could harm somebody or something, the grating will nullify the danger.

5. Longevity

It doesn’t matter how well our industrial flooring operates if we do not have the guarantee that it will last for a long time. Replacing the flooring every five years or so would be too pricey because of the constant installations we’d have to do and the material spent on that.

With GRP grating systems, we have a longer-lasting source of flooring. The GRP grating systems are capable of lasting for over 25 years. This longevity makes them incredibly valuable because they provide a solution that won’t need to be constantly revisited. This trait is further enhanced by the low amount of maintenance the grates require generally. After the installation, there will be very few things to worry about.

6. A ton of choices

There are plentiful choices to be made when getting GRP grating systems installed. These will vary the functionality of the industrial flooring as well as aid you in providing the support for things you need them to do.

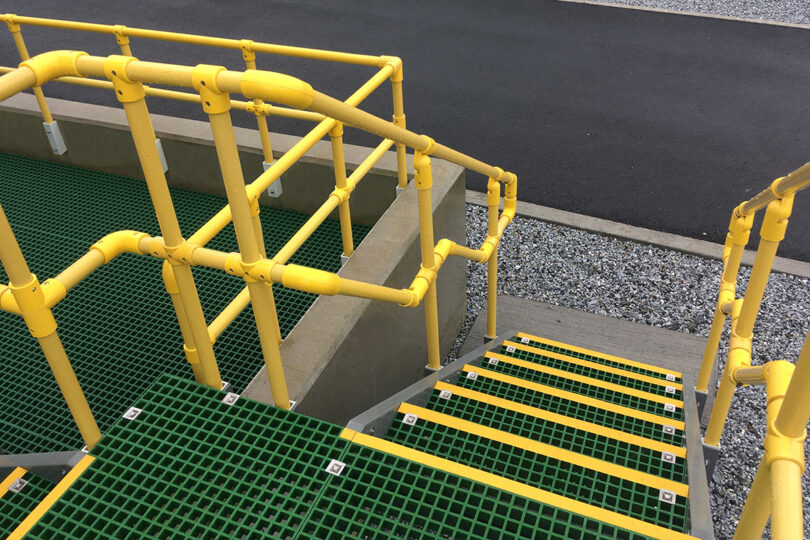

The versatility is well appreciated especially when it still comes bundled with the other benefits of the industrial flooring. It means we can confirm what we need and assure maximum satisfaction from a purchase such as this. Being able to model around the design of our interiors and exteriors is necessary for the sake of creating consistent support for the whole system. With all the handrails, stairs, and other additions to boot we will be fully equipped to assemble a proper flooring.

Conclusion

With the provided benefits, we can see some key sources of beneficial applications from installing GRP grating systems. The problems that can be run into by industrial floorings are oftentimes very problematic. Not only can they disturb the overall work of our area but cause horrible safety problems if not dealt with. Those problems can lead to bad injuries and cause a whole slew of issues across the board. With the financial consequences these bring, it’s better to simply avoid them. The fact that the GRP grating system is so cheap makes it a great addition overall.